With a 35-year legacy in the pet food and pet products industries, our roots run deep—beginning with two decades of leadership at Nestlé Purina. We were early pioneers in building partnerships with farm and feed chains, buying groups, and distributors, ultimately formalizing this expertise through FarmandFeed.net. Our deep industry knowledge led to the creation of our own dedicated sales and marketing force under PetRetailGroup.net, allowing us to support braAnds from the ground up.

Through PetCulinaryLab.com and Em-Bark.com, we’ve built incubation systems that foster innovation across the pet space, from nutrition to retail. Our cause marketing efforts have further expanded the industry’s impact through the development of programs like PetSpas.org, PetParks.org, and PetWellness.org, which champion pet enrichment, community, and wellness.

Beyond product and brand development, we’ve played a groundbreaking role in television—serving as the original production team behind the Jack Hanna TV shows, launching series like Entrepreneur Magazine TV, and advising key players in in-clinic content delivery, including Petcare TV. This rich history underscores our ongoing commitment to shaping the future of the pet industry across multiple platforms.

The future Pet Culinary Lab (www.PetCulinaryLab.com) is an innovative hub dedicated to advancing the pet care and pet food industry by serving as a central resource for new product development, formulation testing, and private label solutions. Designed to be a collaborative space for pet care manufacturers, start-ups, and industry experts, the lab provides cutting-edge research and development capabilities, including a pilot plant for small-batch production and prototype testing. Companies looking to launch new pet food recipes, treats, supplements, and wellness products can utilize the facility for formulation expertise, ingredient sourcing, and market-ready product testing. The Pet Culinary Lab will also support private label programming, helping retailers, brands, and entrepreneurs create custom pet care lines with high-quality formulations that align with market trends. By fostering innovation and collaboration, the Pet Culinary Lab aims to be a driving force in the future of pet nutrition and wellness, bridging the gap between concept development and commercial-scale production.

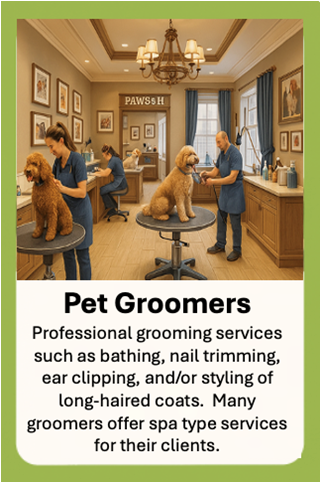

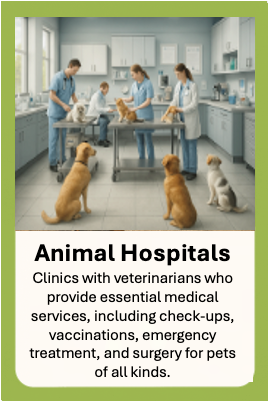

As part of the Co-Packing Network’s and Innovation Business Network’s Pet and Farm and Feed programs, we are expanding our efforts into creating industry campaigns relating to the following areas:

Pet insurance is a healthcare policy for pets that helps cover unexpected veterinary costs, including accidents, illnesses, and routine care.

Many pet insurance plans reimburse a percentage of veterinary bills, making pet healthcare more affordable.

Some policies also cover preventative care, prescription medications, and alternative treatments like acupuncture for pets.

Pet rescues are nonprofit organizations dedicated to saving, rehabilitating, and rehoming abandoned, neglected, or stray animals.

Many rescues specialize in specific breeds or types of pets, ensuring they find suitable forever homes.

Unlike shelters, rescues often rely on foster homes rather than housing pets in a centralized facility.

Pet hotels are luxury boarding facilities that provide temporary lodging, care, and entertainment for pets while their owners are away.

High-end pet hotels offer private suites, play areas, grooming services, and even spa treatments.

Many pet hotels provide 24/7 supervision, ensuring pets receive personalized attention and medical care if needed.

Doggy daycare is a supervised facility where dogs can socialize, exercise, and receive care while their owners are at work or away.

These centers provide structured playtime, group activities, and rest periods to keep dogs happy and engaged.

Some doggy daycares offer obedience training, agility courses, and specialized programs for puppies or senior dogs.

Pet breeders are individuals or businesses that specialize in selectively breeding animals to maintain or improve breed standards.

Responsible breeders focus on health, temperament, and genetic diversity, ensuring pets are well-socialized before adoption.Ethical breeders provide health screenings, veterinary care documents

to guarantee the pet’s lineage and well-being.

The founders of the PetRetailGroup.net, FarmandFeed.net, along with the Sports Retail Group, have been pioneers in developing and supplying innovative retail formats that serve a wide range of industries, including farm and feed stores, hotel pantries, camp stores, marina shops, and more. Their expertise in curating unique retail experiences has helped shape new concepts and introduce specialized products that cater to the evolving needs of consumers.

Looking ahead, they are launching transformative programs to empower farms and ranches, including

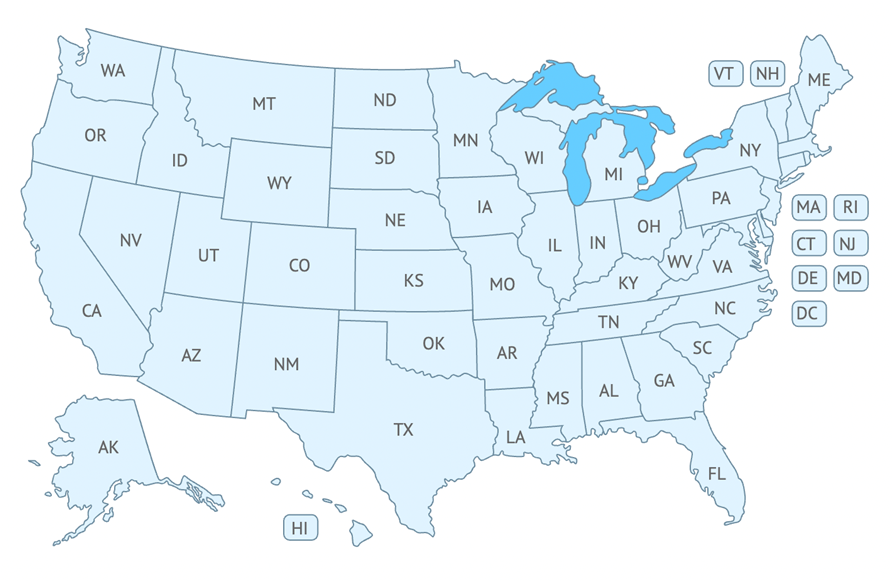

We are showcasing a diverse range of pet retail stores, farm supply outlets, and related specialty retailers across the country—organized by state. This state-by-state approach highlights regional trends, unique store formats, and local favorites, offering valuable insights into how communities support pet owners, farmers, and animal lovers alike. From independent feed stores in rural towns to modern pet boutiques in urban centers, our coverage celebrates the full spectrum of available brick-and-mortar locations.

Pet Beds & Furniture

Small Animal & Bird Supplies

Pet Grooming & Hygiene

Pet Apparel & Accessories

Travel & Outdoor Gear

Pet Health & Wellness

Pet Training & Behavior

Pet Toys & Entertainment

Cleaning & Waste Management

Aquatic & Reptile Supplies

Pet Food & Treats

Pet Wellness has become a key focus in the pet care industry, with manufacturers and retailers embracing holistic, health-focused solutions to meet the growing demand from pet owners. Premium nutrition, functional ingredients, and alternative health treatments are driving innovation in pet food, supplements, and grooming products. Pet food manufacturers are incorporating superfoods, probiotics, CBD, and sustainable proteins to enhance pet health, while retailers are expanding their offerings to include fresh, raw, and freeze-dried diets. Personalized pet nutrition—including custom meal plans and breed-specific diets—is gaining traction, along with functional treats designed to support joint health, digestion, and anxiety relief.

In grooming and wellness, aromatherapy, pet-safe essential oils, and spa-inspired treatments are becoming mainstream. Retailers are also enhancing the customer experience with subscription services, mobile pet wellness pop-ups, and digital pet health tracking tools. As pet owners continue to prioritize longevity and quality of life for their pets, the pet wellness category will remain at the forefront of product innovation and retail expansion.

United Vet Trade Show

The United Vet Trade Show is part of the U.S. Vet Shows, a series of veterinary conferences held across the United States. These events provide veterinary professionals with opportunities for continuing education, networking, and exposure to the latest veterinary products and services. Each show features clinical, business, and nursing tracks, offering versatile education for the entire practice team. Attendees can participate in lectures, hands-on workshops, and explore exhibitions showcasing the latest advancements in veterinary medicine. The shows are hosted in exciting destinations, allowing participants to combine professional development with enjoyable travel experiences.

www.USVA.net

Global Pet Expo

The Global Pet Expo is an annual trade show presented by the American Pet Products Association (APPA) and the Pet Industry Distributors Association (PIDA). Held in Orlando, Florida, it is one of the largest pet industry events in the United States, attracting exhibitors and attendees from around the world. The expo showcases a wide array of pet products, including new product launches, innovations in pet care, and emerging industry trends. It serves as a platform for pet product manufacturers, importers, retailers, and distributors to connect, establish business relationships, and stay updated on the latest developments in the pet industry.

www.GlobalPetExpo.org

SuperZoo

SuperZoo is one of the most-attended pet industry trade shows in North America, established by the World Pet Association (WPA) in 1950. Held annually in Las Vegas, Nevada, SuperZoo brings together pet retailers, product suppliers, and service providers for a comprehensive showcase of the pet industry. The event features educational seminars, grooming competitions, and a vast exhibition floor where attendees can explore the latest pet products and services. SuperZoo serves as a hub for networking, professional development, and discovering new business opportunities within the pet retail sector.

www.SuperZoo.org

The Contract Manufacturing Alliance (Contract Manufacturers, Pilot Plants, Private Labelers, Commercial Kitchens, Food Innovation Centers and More) Was Created to Be the Key Resource For Anything to Do With Manufacturing Consumer Products (For Start-up and Emerging Brands).

Established in 1992, the Contract Packaging Association (CPA) is the national, non-profit trade organization dedicated to promoting the growth and welfare of firms in the Contract Packaging / Manufacturing industry and related businesses. We offer exposure and programs designed to foster growth within our member firms.

The Co-Packing Network is a comprehensive national Consumer Packaged Goods (CPG) advisory group deeply rooted in the diverse US and Canadian consumer product manufacturing industries. Celebrating our 100-year anniversary, our expansive history spans supermarkets, wholesaling, manufacturing, owning brands, and beyond.

The CPA's Request for Quote (RFQ) tool allows an automated submission to CPA Members to securely submit their project details and needs. Your Request for Quote will be dispatched to CPA Members whose capabilities match your project needs, and if they can assist you, will contact you directly about their services and capabilities.

The team manages the request all-the-way through to end up with successful results. We also can become a project manager to manage the whole process (search, secure and work with one or more contract manufacturers).

The team manages the request all-the-way through to end up with successful results. We also can become a project manager to manage the whole process (search, secure and work with one or more contract manufacturers).

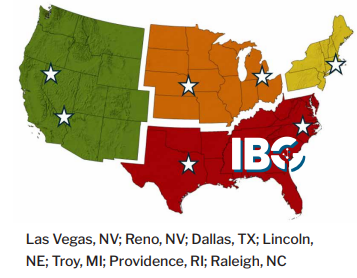

The Innovation Business Group was created to help start-up and emerging consumer brands understand the diversity of retail, food service, hospitality, medical and institutional channels that are out there to do business with.

* IBG is helping start-up and emerging brands with their sales and marketing efforts in relation to medical, wellness and nutrition formats.

The Innovation Business Group (IBG) is an extension of the Contract Manufacturing Alliance (www.ContractMFG.org) which helps consumer brands (of all-sizes) with their contract manufacturing search and relationship needs. Our roster of contract manufacturers, co-packers and packagers is over 43,000.

Our family has been involved within the consumer product industry (US based manufacturing, retailing, distribution) since the early 1920’s. From the first generation to the latest, our best practices have been handed down over time leading to a long legacy of successes in the business (manufacturing, retailing, distribution and more).